Next-Generation 3D Sensing Light Source with Edge-Emitting Laser Diodes

Publish Date:2020-10-01

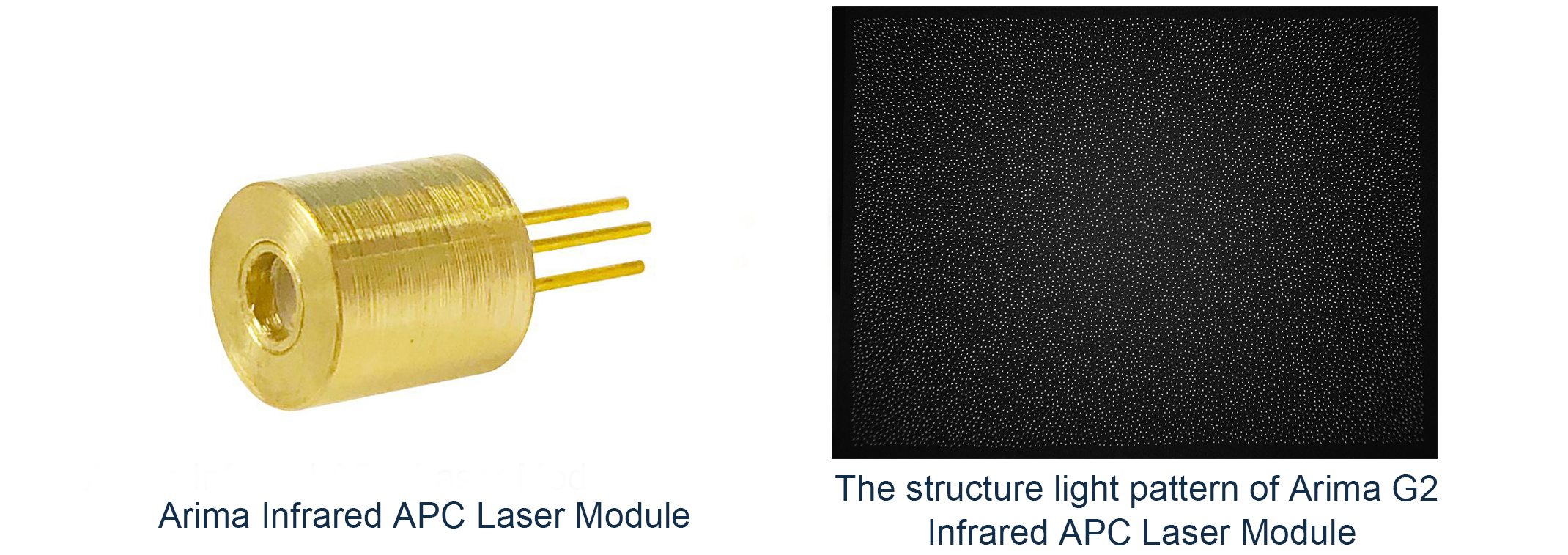

Arima Lasers develop technology using edge emitting laser (EEL) as structure light source, combined our original automatic power control (APC) patent, and launched the Infrared APC Laser Module for 3D sensing application.

Different from the common periodic pseudo-random random dot array when using VCSEL, Arima EEL Infrared APC Laser Module can project truly random dots. In 3D sensing applications, it can get higher accuracy and less noise. The 1st generation (G1) modules have achieved great success, and their performance exceeds that of light source modules using VCSEL.

To further improve its performance, the 2nd generation (G2) φ6.5mm module contains TO56 830nm/850nm/940nm laser source and a diffraction optical element (DOE) that have integrated collimation capability. The original optical design makes the zero-order diffraction spot completely disappear and improves safety. The light output power of module up to 160mW, random dot more than 30,000 and field of view is (H)70°× (V) 55°.

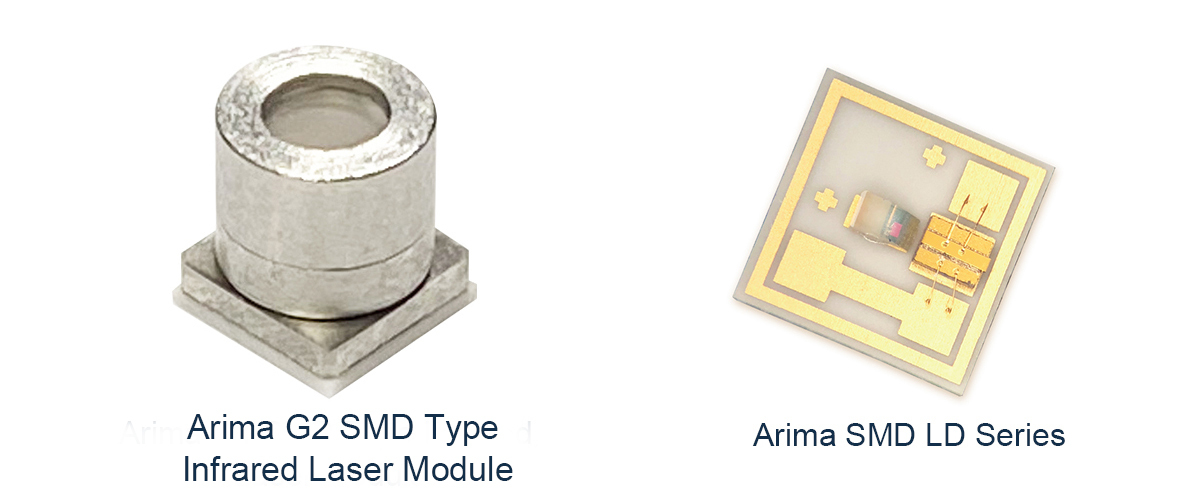

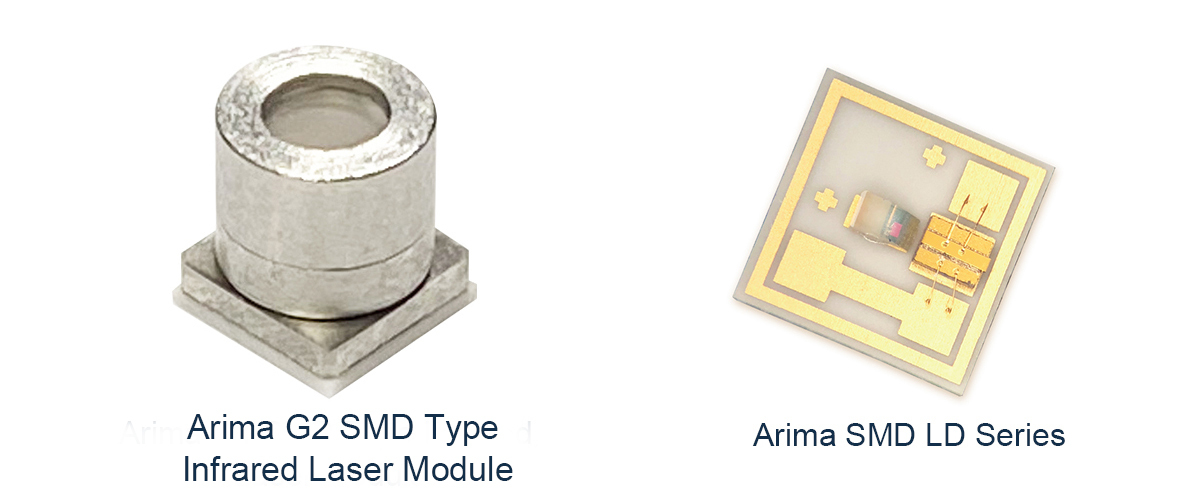

In addition, Arima Lasers has developed surface mount technology (SMT). This can greatly reduce the volume of the package. And can be applied to reflow process. The 1st generation (G1) SMD Type Infrared Laser Module is expected to be launched in the fourth quarter of 2020.

For customers who do not need optical modules, Arima Lasers can also provide TO or SMD package laser. If there are requirements for other specifications, Arima Lasers also provide customized services.

Choose EEL or VCSEL? The High Power 3D Sensing Light Source

The application of 3D sensing is currently booming. At low power demand, Vertical Cavity Surface Emitting Laser (VCSEL) have become the first choice for 3D sensing laser light sources because of their cost advantages and simple optical design. However, the increase in accuracy and range requirements puts the power and reliability of the light source to the test. In order to provide high-quality light sources, Arima Lasers has developed a new generation solution with Edge Emitting Laser (EEL). And its measured results on the 3D sensing system show better performance than traditional VCSEL light sources.

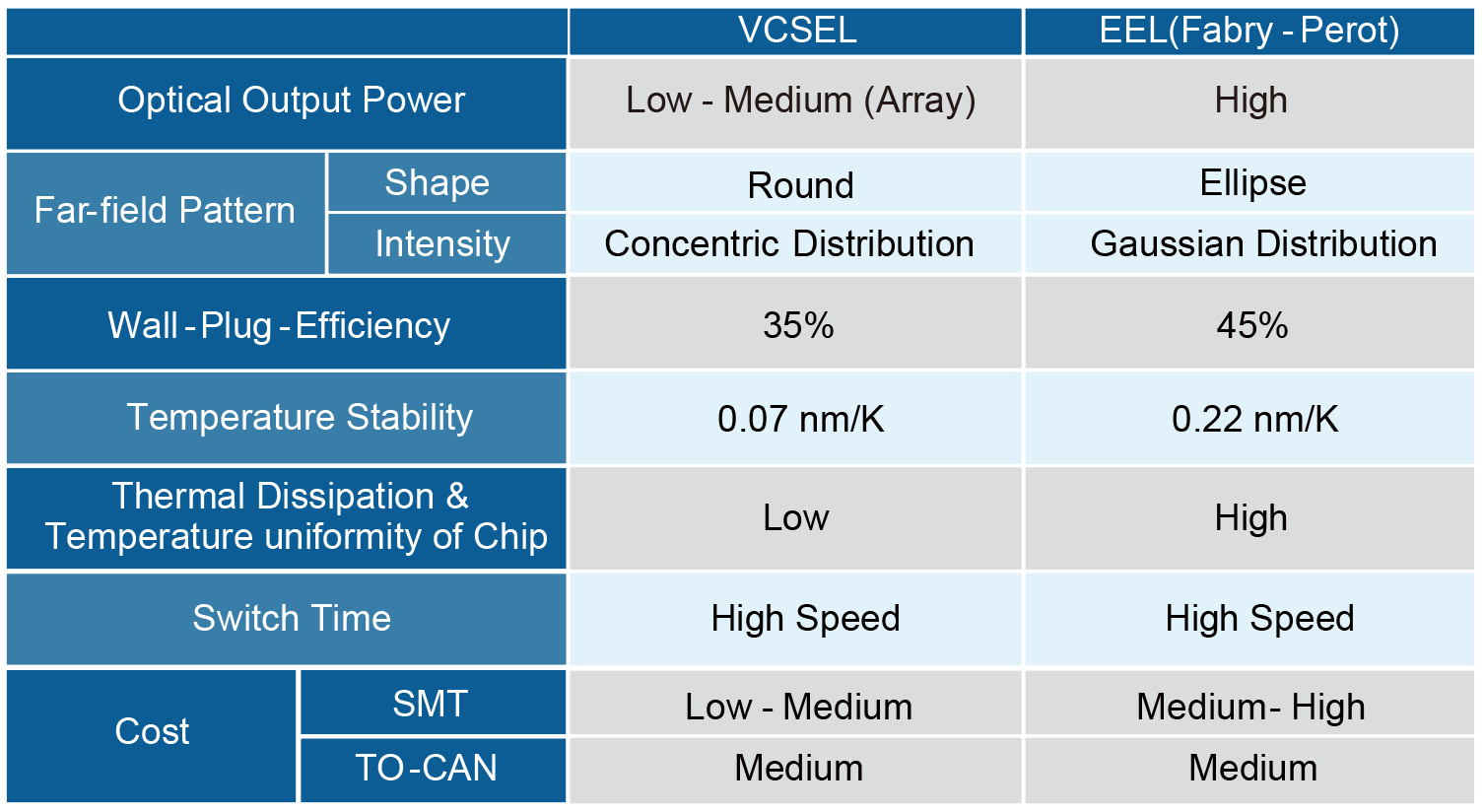

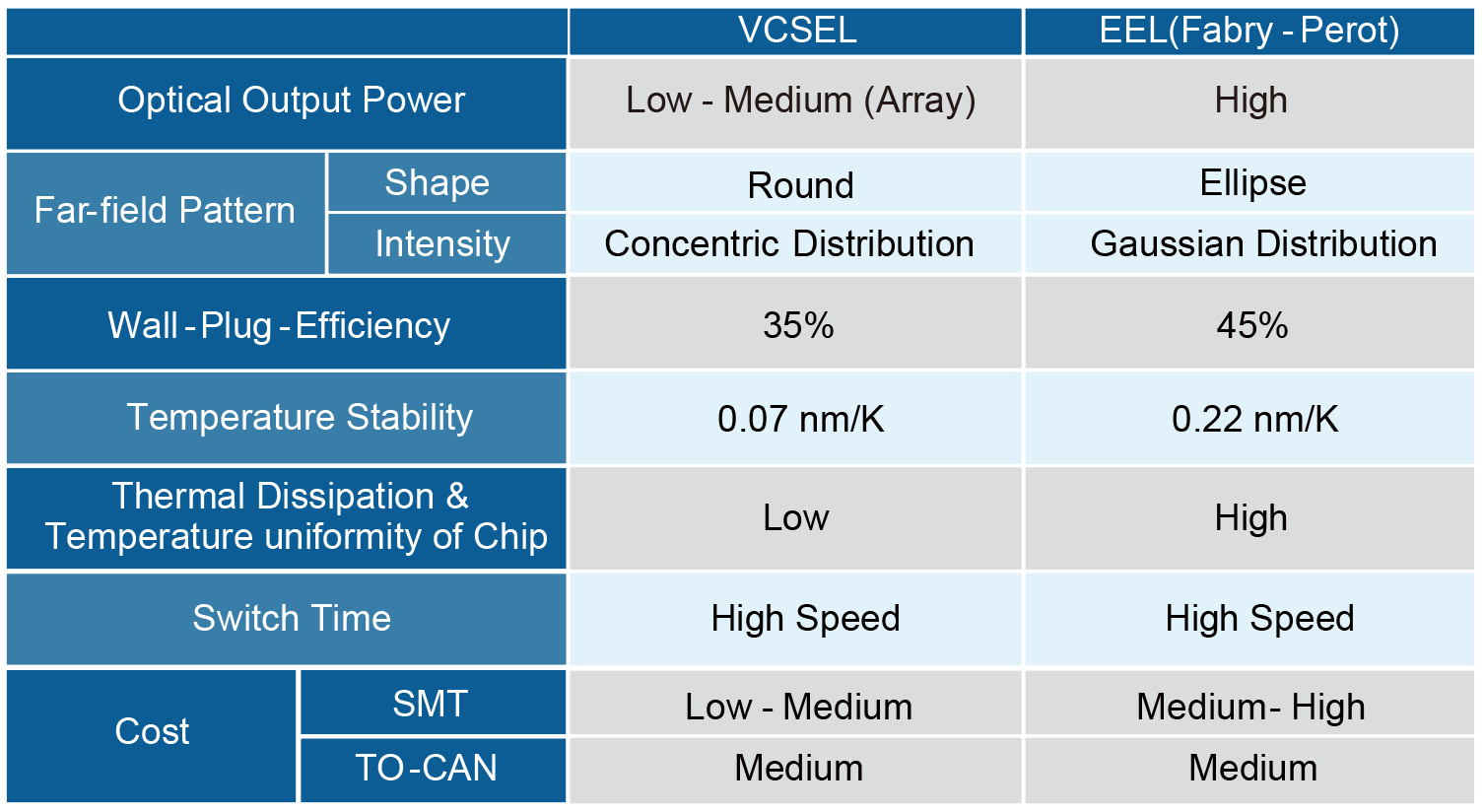

Compared with VCSEL, EEL has the following advantages,

1. High light output power:

Current, the reachable power of a VCSEL in Single-Mode is about 4~5mW, and in Multimode is about 8~9mW. Arranging them in an array is a common way to further increase power. However, considering the chip design and size, the power that this method can increase is still limited. In contrast, EEL only needs a single chip to achieve high power.

2. High Wall-Plug-Efficiency (WPE):

WPE of VCSEL is about 35%, and EEL is about 45%. When used at low power, the WPE difference between EEL and VCSEL may not be so obvious. However, when used at higher power, low WPE means VCSEL will consume more energy generate more waste heat. This will cause a variety of undesirable effects

3. Good thermal dissipation:

The stability and reliability of laser light sources are closely related to temperature. High temperature will cause negative effects such as wavelength shift, reduction of WPE, and shortened service life. Due to the structure of the VCSEL, generally the P-side that generates light and heat cannot directly contact the heat sink, and the heat is easy to accumulate. Especially in the high output power state, this effect will be more significant. On the other hand, EEL can make the P-side and heat sink directly bonded, and the thermal dissipation capacity and temperature uniformity of the laser chip are far better than VCSEL.

Based on the above, it can be found that when using at low power, VCSEL is indeed the most reasonable choice of 3D sensing laser light source because there is almost no need to consider thermal and efficiency. However, these negative effects will gradually increase as the demand for power increases. In contrast, the cost performance of EEL is lower than VCSEL at low power. But in the high-power field, EEL is a more potential choice than VCSEL.